ULO for berries

The storage of products of berries in a refrigerated state is the most reliable and effective method of "preservation".

For storing berries on industrial scale and large volumes, the RGA/ULO (regulated gas atmosphere/atmosphere with ultra-low oxygen content) is used.

With the help of this technology, the ripening of the product slows down and the intensity of breathing decreases, which preserves the quality and taste, vitamins, increases shelf life and reduces losses, maintaining resistance to diseases.

The ULO base is a special equipment that maintains the optimum concentration of gases - oxygen, carbon dioxide. For each berry sort, certain storage conditions are selected: temperature and gas atmosphere.

As the harvested berries continue to "live" and "breathe", metabolism is accelerated, and oxygen is converted into carbon dioxide. Reducing the oxygen level in the atmosphere of the storage chamber limits the "breathing" process and, accordingly, slows down their aging.

The basis of the RGS technology is the tightness of the storage chamber, which makes it possible to control accurately the gas content inside the chamber.

4 main storage systems in ULO:

Hand-held pallet storage

Individual O2 / CO2 control for pallets in hand-operated RGA bags. Short-term storage, for example, in transport.

- Features:

- Suitable for short-term storage;

- Manual feed of CO2;

- Measure O2 / CO2 every 2-3 days;

- Labor intensive work;

- Small volumes;

- Low cost.

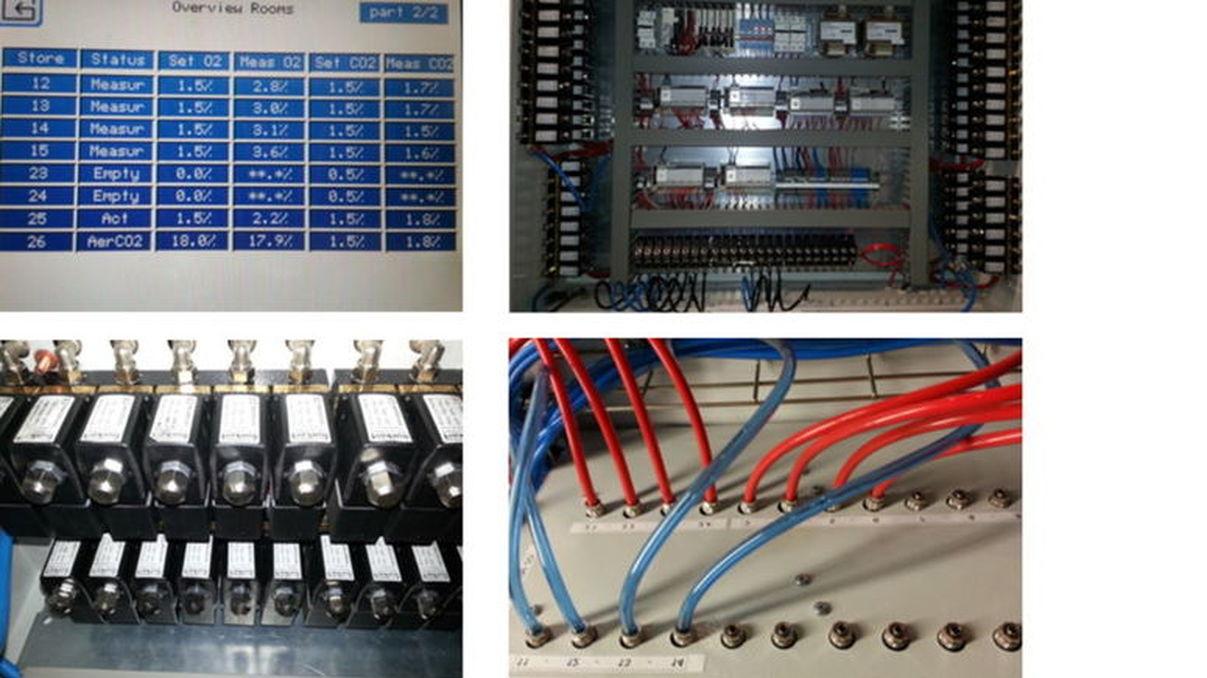

Pallet automatic system:

• Individual O2/CO2 control for pallets in RGA bags by an automatic system, modular and with the possibility of expansion of the system;

• Medium/long-term storage of 32 pallets per module;

• Simple and versatile storage system for various product types.

- FEATURES:

- Modular with 32 RGA bags;

- Perfect O2 / CO2 regulation per bag;

- Easy to turn off / on (connect/disconnect);

- Easy to manage;

- 3 tubes are connected to each bag (Measurement - O2 / CO2 supply; N2 supply).

- The system consists of:

- Control system + analyzer;

- N2 generator;

- Source of CO2 (cylinders);

- Tubes and connectors;

- Air Compressor.

- Features of the control system:

- The tubes are easy to connect;

- Easy access to system elements;

- Office from the mobile device.

Sectional storage system:

Centralized O2/CO2 control system: 10-60 pallets with RGA bag connected to the central system of supply/selection tubes and mixing unit for O2/CO2 monitoring. Medium/long-term storage, large sections 20-250 pallets.

- Features:

- Pallets in RGA bags according to groups/sections;

- Each pallet is connected by two tubes to the central tube of selection and supply to which the mixing system is connected by the fan;

- 10 - 60 pallets per section;

- Precise adjustment of O2/CO2 levels due to circulation in the section;

- Energy efficient/economical.

- Equipment:

- N2 generator + CO2 cylinders;

- Control system + analyzer;

- Each section with:

- Mixing system, ventilation and O2/CO2/N2;

- Pipelines of supply/drain + tubes;

- Connector valves for each bag.

The mixing system is located in the center of the supply and selection pipelines. The fan creates a constant flow of air through all connected 10-60 RGA bags with pallets. This ensures optimum levels of O2/CO2.

To the mixing system are connected:

• O2/N2/CO2 supply valve

• Measuring valve

• A Fan for circulation

Mini-RGS camera

CSG camera with O2/CO2 monitoring system. Medium/long-term storage, large storage capacity.

- Features:

- Any storage capacity;

- Long-term storage;

- Precise control of O2 / CO2 levels;

- H2O measurement (option);

- Optimum storage temperature.

- EQUIPMENT:

- Sealed chamber and doors;

- N2 generator (nitrogen);

- CO2 cylinders;

- Control system + analyzer;

- Ventilation fan