A high quality cooling is a guaranteed profit

On a harvest’s way from field to table a farmer is the most vulnerable one, because working with products, that rot fast, can be risky.

On a harvest’s way from field to table a farmer is the most vulnerable one, because working with products, that rot fast, can be risky.

A right way to gather and finish products has a direct influence on the effectiveness of economy. It is important to cool the harvest, decrease the loss of moisture and intensity of breathing, slow down the reproduction of microorganisms and preserve the appearance of fruits right after the gathering from a field.

Advantages of shock coolhouse:

• Slows down the breathing of the fruits, increasing shelf life.

• Preserves their appearance, taste and smell, decreases the loss of moisture.

• Prevents the growth and reproduction of fungi, microorganisms, bacteria, especially on berries.

Much attention should be paid to the speed with which heat is diverted from products. Berries lose their quality during slow cooling.

For each specific product, there are different cooling systems, so the manufacturer should understand their benefits and limitations. Properly selected system provides the desired cooling rate, which reduces losses from dehydration.

FORCED AIR COOLING

This is the most common method for fast cooling of berries, fruits and freshly cut flowers. The cooled air is used by this system as a cooling environment. It is blown through products packed in containers or installed on pallets. It is important to calculate accurately the airflow for a certain quantity of products.

The cooling time varies from an hour or more and depends on the packaging of the product. It is best to first use the camera for quick cooling, and then move the product to a storage chamber. Such system is less costly in terms of electricity consumption.

System of forced air-cooling can be used in an already built refrigeration chamber to reduce the cooling time. The work of the cooler has a natural effect of removing moisture from the air when it passes through the evaporator, but during the design of the fast cooling chamber, this effect can be minimized by the proper selection of the form of the cooler. At the beginning, the product loses heat quite quickly, but then this process is slowed down.

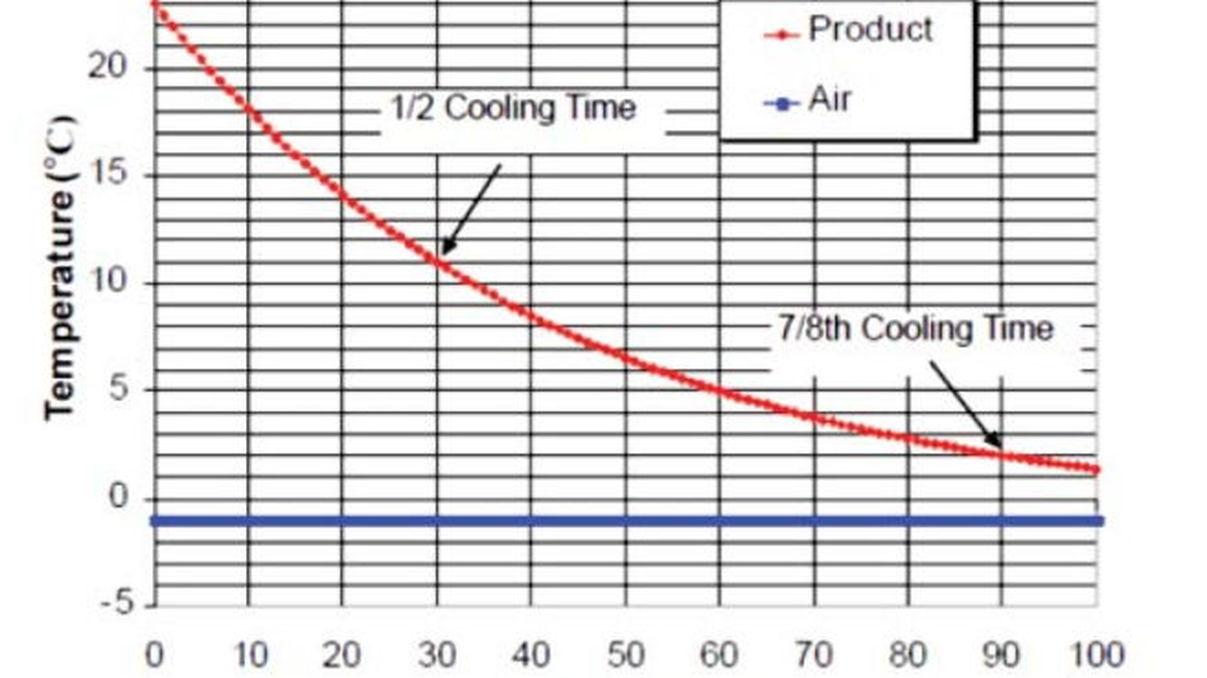

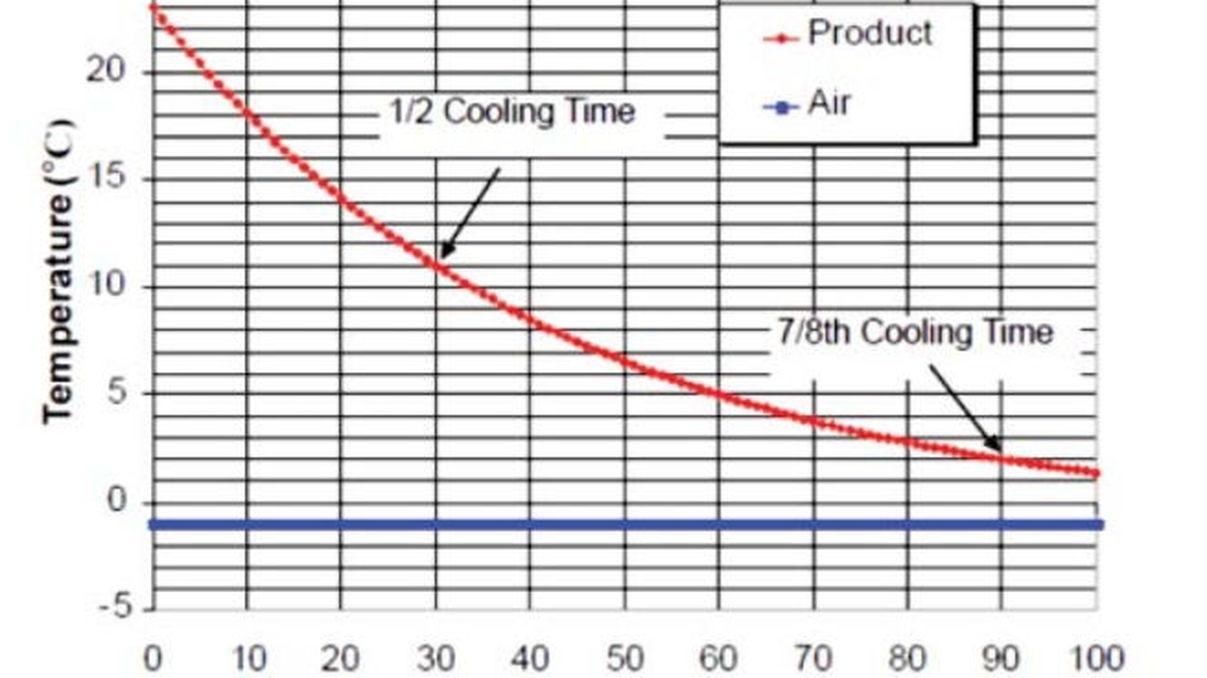

According to a research by the Department of Biology and Agro-Engineering of the University of California, berries should be cooled according to the 7/8 rule.

This means that 7/8 of the temperature of the product coming from the field must be discarded (lowering the temperature) for the time necessary to remove 1/8 of the temperature.

For the experiment, the berries were cooled slowly to find ½ cooling time and extrapolate it to 7/8 time. In this case, 7/8 time is equivalent to three times ½ time.

Chart 1 shows an ideal cooling curve with constant air temperature. The following output data were used to create the graph: product temperature – 23 °С, the temperature of the cooling air is -1 °С.

The graph shows that the removal of 7/8 of excess heat lasts three times longer than 1/2 removal. Consequently, the temperature decrease by 1/2 is a decrease of 11 °С, and a decrease of 7/8 is a decrease to 2 °С.

The time required to reduce the temperature by 1/2 – 30 minutes, and 7/8 – 90 minutes. However, it should be borne in mind that the cooling rate for different types of packaging in commercial systems using cooling coefficients of 7/8 will be different.

The reason is that it is not enough to take into account the refrigeration capacity, also the air exchange through the product and the packaging should be taken into account. For correct and quick cooling, ventilation systems with precise selection of fans are designed to comply with the 7/8 rule, regardless of packaging type and quantity of products.

In the case of non-compliance with the 7/8 rule, the berries will be more likely to deteriorate, reducing their period of shelf life.

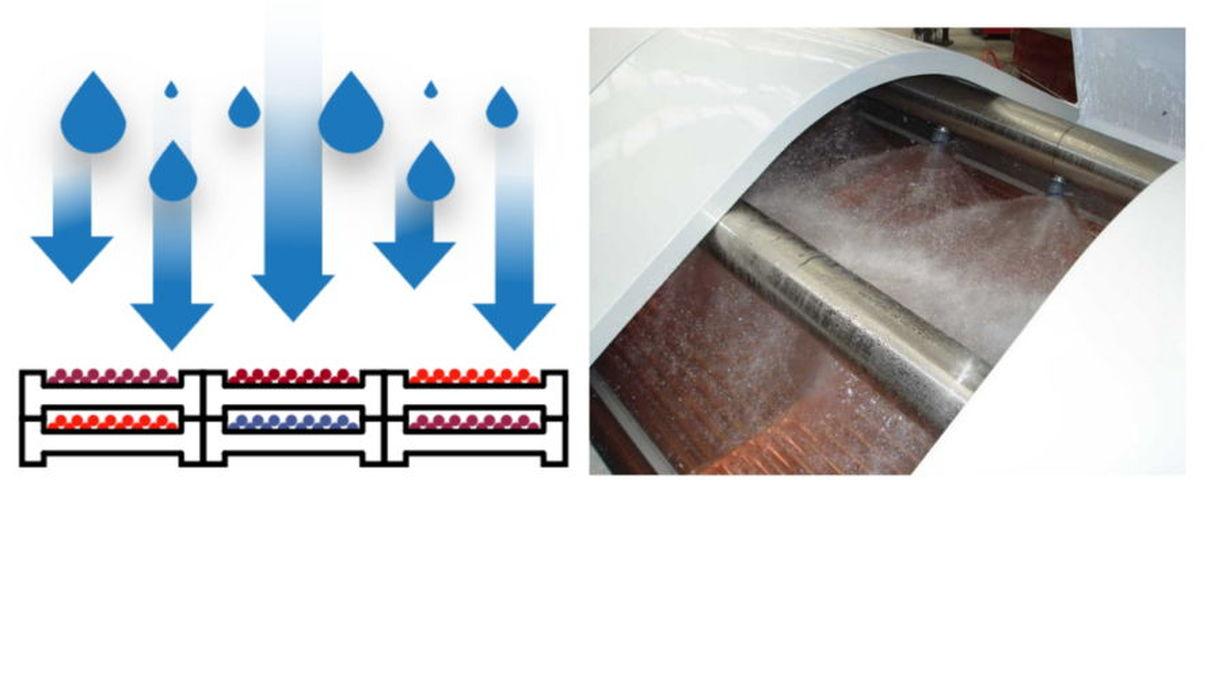

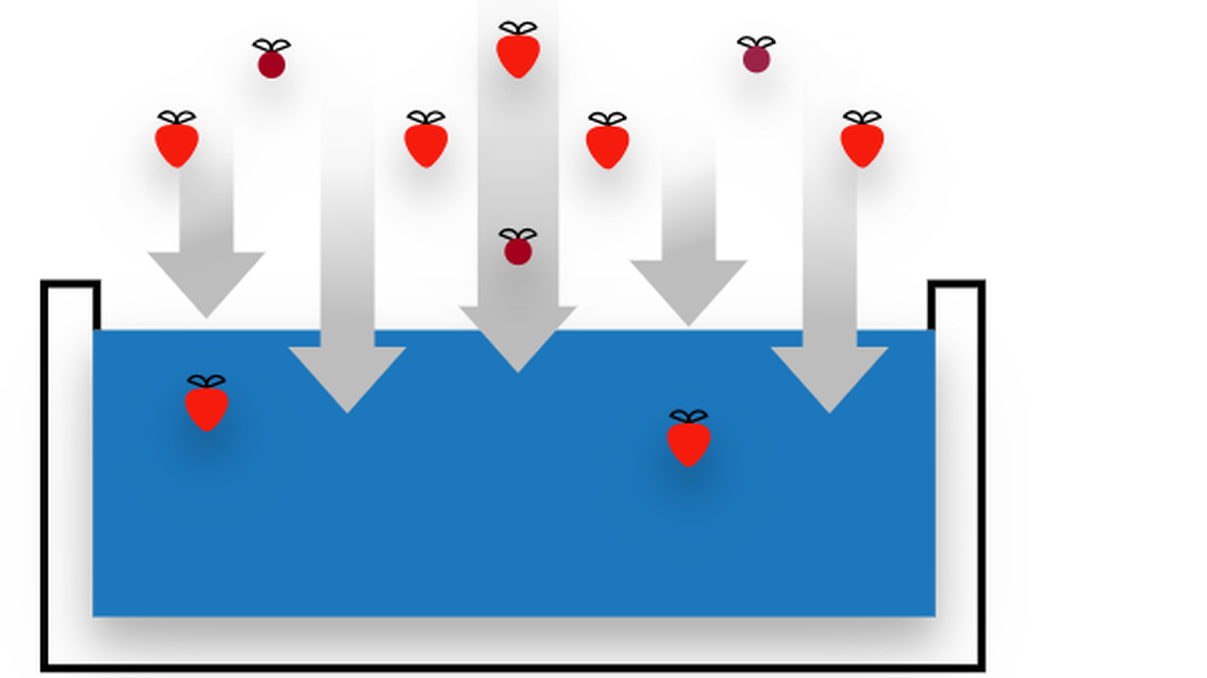

HYDROCORRECTION

This cooling technology is based on the movement of cold water around the product through the shower system or by immersing products directly into cold water.

This type is widely used for root crops, stem and flower types of vegetables, melons and some fruit crops. Hydro coolers do not lead to loss of moisture during cooling. On the contrary, they can moisten a slightly faded product. Since water can be a carrier of microorganisms and plant decay products, it should be filtered and disinfected. As a rule, hypochloric acid HClO or gaseous chlorine are used for this purpose.

Sprinkler coolers of the shower type can be equipped with a moving conveyor for continuous operation or can operate in batch mode. Small-sized products such as cherries and cherries are cooled in less than 10 minutes. Large-diameter products, such as melons and watermelons, are cooled for 45-60 minutes.

Submersible chillers are suitable for a product that dries in water. They usually cool more slowly than the shower, as water flows more slowly around the product.

VACUUM COOLING

Vacuum cooling is used for leafy vegetables, fruits, cut flowers and salads. This technology provides cooling through the rapid evaporation of water from the surface of the product. Loss of moisture at 1% leads to product cooling at 6 °C.

For vacuum cooling, the product is placed in a steel chamber, and vacuum pumps reduce pressure in it to 4.6 mm Hg. Water boils under pressure from 20 to 30 mm Hg. depending on temperature. This leads to rapid evaporation of moisture and rapid cooling. At the end of the cooling cycle, the pressure is equal to 4.6 mm Hg. water, and boils at a temperature of 0 °C.

If the product is kept for such a long time, it can cool to 0 °C. For leafy vegetables that release moisture quickly, cooling can last 20-30 minutes, even when the product packed in plastic or film. The products lose 2 to 4% of the weight during cooling, depending on the initial temperature. Spraying with water before cooling minimizes the loss of moisture product.