Have questions? Our manager will provide answers to them.

Storage of carrot

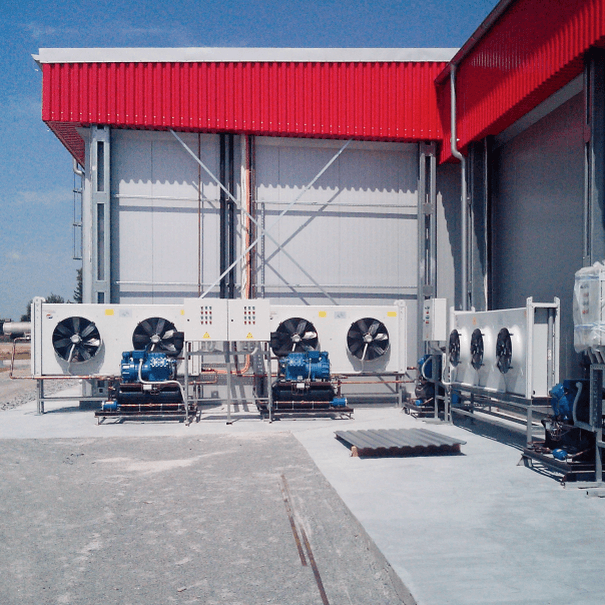

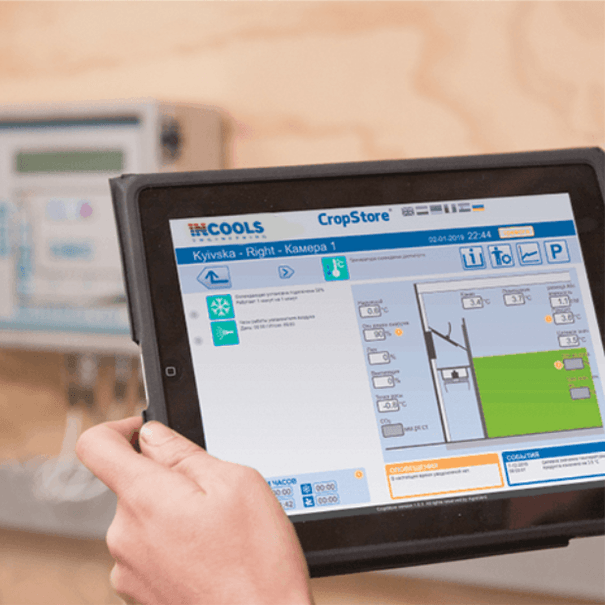

«INCOOLS» has extensive experience in building carrot storage facilities. We know all the details of the technology of storing root crops, therefore, the design and construction of storage facilities are carried out strictly according to the necessary criteria.

COMPLETED PROJECTS

more projectsOTHER DIRECTIONS

Each product has its own storage features.

To get the consultation

Have questions? Our manager will be happy to provide answers to them.

Thank you

Your application has been sent successfully. Our manager will contact you soon

To calculate the estimated cost of the equipment complete the questionnaire

Application for equipment calculation